Ningxia enterprises enhance global resource allocation capability with the help of "one belt and one road"

Reporters recently learned from Ningxia Tianyuan manganese industry group that the group was formally put into production in Garner's mine, marking that the world's largest electrolytic manganese metal enterprise has further accelerated the process of distributing the global market by means of "one belt and one road", and the ability of Ningxia enterprises to allocate resources worldwide has been further enhanced. As early as November last year, Tianyuan Manganese Group successfully acquired CML Australia United Mining Company, which has been widely concerned by the industry. The operation of the mine in Ghana is a further deepening of the international merger and acquisition of Ningxia Yuanmanganese Group. Tianyuan Manganese Industry has its own mineral raw material base abroad since then.

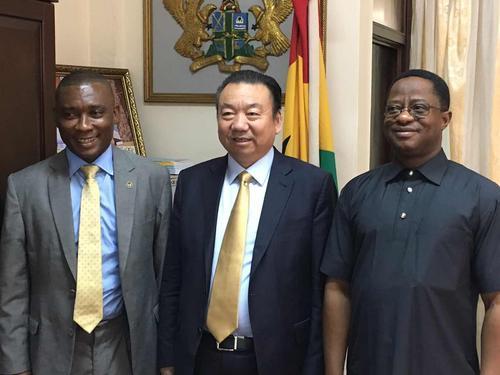

On May 11, the leadership of Ningxia Yuanmanganese Group met with the senior government of Ghana and reached an agreement. In addition to mining manganese ore in Ghana, Tianyuan manganese industry will export large quantities of cement produced by manganese slag to Ghana, which means that the circular economy chain of Ningxia Yuanmanganese industry will be internationalized.

China is poor in manganese. Among the proven mineral resources, manganese ore reserves are low and concentrated in "manganese triangle" areas such as Chongqing, Guangxi and Guizhou, with low ore grade. Ningxia Yuanmanganese Group is the world's largest electrolytic metal manganese production enterprise. In recent years, relying on technological progress and cost advantages, it has become the leader of technological progress, clean production and recycling development. In 2016, Tianyuan manganese industry ranked 349 of the top 500 Chinese enterprises, 109 of the top 500 Chinese private enterprises and 65 of the top 500 Chinese private manufacturing enterprises. In view of the disadvantage of poor manganese and low grade, low manganese content and high impurity content of manganese ores in China, breakthroughs have been made in key technologies through independent innovation, and the bottleneck of low product quality and efficiency has been broken through with foreign ores, making it the only manganese production enterprise in China that uses all imported ores. At present, the production capacity of metal manganese in this enterprise reaches 800,000 tons, which accounts for one third of the world market share and consumes more than 3 million tons of imported manganese ore every year. With the implementation of the 13th Five-Year Plan, by 2020, the production capacity of Tianyuan manganese series products will reach 3 million tons, and the annual consumption of imported manganese ore will reach 8.5 million tons.

The Republic of Ghana, located in the west of Africa and the north coast of the Gulf of Guinea, is rich in high-quality manganese ores. Its domestic manganese resources are 113 million tons, ranking first in the world. Tianyuan manganese industry has imported manganese ore from Ghana, South Africa and other countries for nearly 10 years. In the long-term use, Ghana ore is obviously superior to other countries at home and abroad. Its main characteristics are large reserves. The world's manganese ore reserves are mostly in African countries, but most of them are manganese oxide ores, manganese carbonate ores are less, and Ghana is manganese carbonate ores, and the reserves are the first in the world. The second is high grade. The grade of domestic manganese ore is only about 13%, while that of Ghana's manganese ore is over 28%. Using 3.5 tons of Ghana's ore, one ton of metal manganese can be produced, while using domestic ore requires 8 to 10 tons, or even 12 tons. Third, the content of impurities is low. Especially for sulfur and carbon content, Ghana ore is obviously lower than domestic ore. Fourth, the use of fewer accessories. The imported ore is far lower than the domestic ore in the production of 1 ton product input, and the corresponding use of sulfuric acid, sodium fumei, selenium dioxide and other auxiliary materials is less. Fifth, more energy-saving and environmental protection. Domestic ore produces 1 ton of metal manganese products, producing more than 8 tons of manganese slag. Ghana ore produces only about 2.5 tons of manganese slag. With less manganese slag, the pressure of environmental protection is small, and the cost of transporting manganese slag is also significantly reduced. Moreover, the use of manganese carbonate reduces the production link of roasting and reduction, and the carbon emissions in the atmosphere are also reduced. Sixth, the leaching rate is high. After years of technological improvement, Tianyuan Manganese Industry has explored a two-stage leaching method to leach manganese ions from ores, making the leaching rate of manganese ions in ores reach 92%. "In the past 10 years, Ningxia Yuanmanganese Industry Group has explored and developed a set of production technology and equipment suitable for Ghana's ores, using Ghana's ores handily, more skilled, and the output and quality of products are more stable." Gao Xuexiang, deputy general manager of Ningxia Yuanyuan Manganese Industry Group, said that the production of Tianyuan Manganese Industry in mines in Ghana means that the raw material supply of Tianyuan Manganese Industry is more stable and sufficient, which will lay a solid foundation for the further development and strengthening of Tianyuan Manganese Industry.

At the beginning of 2014, the company planned to invest 1.507 billion yuan in two cement clinker production lines with a daily output of 4500 tons and supporting low-temperature waste heat power generation projects. One of the production lines has been put into operation and successfully overcome the worldwide technical problems of recycling electrolytic manganese slag. After all putting into operation, Tianyuan Manganese Cement Clinker Project can absorb about 5 million tons of solid waste annually, of which about 342,000 tons are electrolytic manganese slag.

According to the cooperation agreement between the Tianyuan manganese group and the Garner administration, the company will export large quantities of cement clinker to Ningxia, which is an important measure for Ningxia enterprises to "go out" under the "one belt and one road" initiative, and also has positive significance for the structural reform of the supply side.

(Responsible Editor: Administrator)